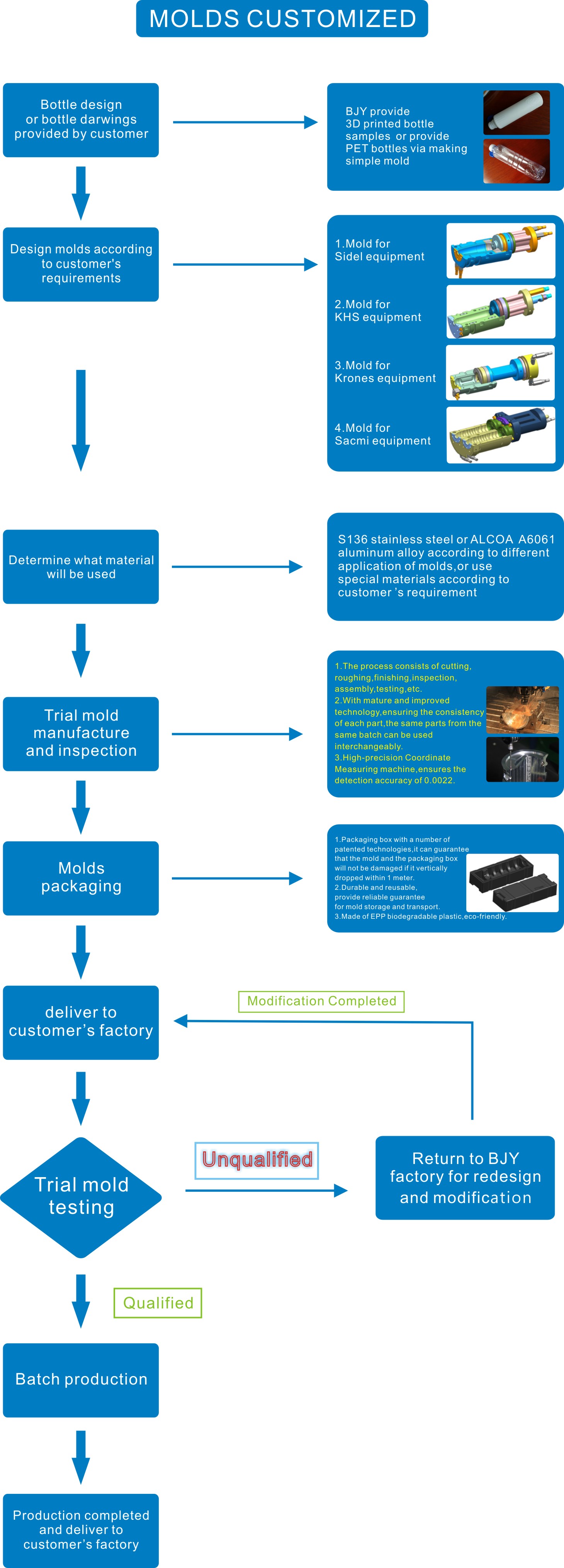

BJY Customized Service Process

I. Bottle/Mold Design or Customer-Provided Bottle Drawings

Provide 3D-printed bottle samples or create simple molds for blowing PET bottles.

II. Mold Design Based on Customer's Equipment

Molds are compatible with blow molding machines from brands such as Sidel, KHS, Krones, and Sacmi.

III. Determine Mold Material

Determine the material based on the mold's intended use: S136 stainless steel, ALCOA A6061 aluminum alloy, or other materials as required by the customer.

IV. Mold Fabrication and Testing

1. Material preparation, finishing, inspection, and assembly.

2. A complete process ensures the consistency of parts, guaranteeing that identical parts within the same batch of products can be freely interchanged.

3. A coordinate measuring machine ensures an inspection accuracy of 0.0022.

V. Mold Packaging

1. Packaging boxes with multiple patented technologies ensure that vertical drops within 1 meter will not damage the mold.

2. Sturdy and durable, reusable multiple times, providing reliable protection for mold storage and transportation.

3. Made of biodegradable EPP plastic, environmentally friendly.

VI. Delivery to the customer's factory for testing.

VII. After passing the test, mass production of the mold begins.

VIII. Production completed, delivery completed.